Click here for details on “low lead dezincing resistant brass rod”.

■The characteristics of SAN-ETSU’s dezincing resistant brass rod

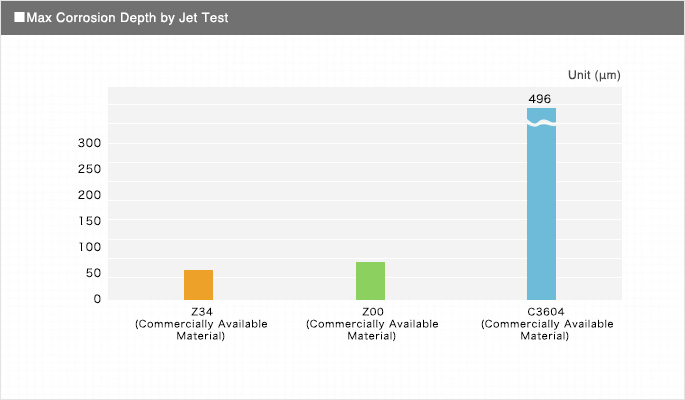

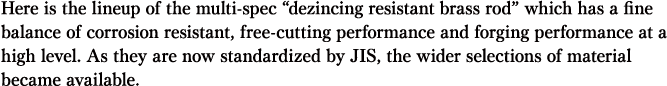

SAN-ETSU METALS offers a full lineup of dezincing resistant brass rod to fulfill various needs of customers under different types of use situations by adjusting the dezincing resistant and free-cutting performance as well as the heat treatment application as required.

The traditional dezincing resistant brass rod requires a heat treatment after

machining when applying a hot forming process. Unless controlling the crystal by

the heat treatment, the high level of dezincing resistant performance was not

achieved.

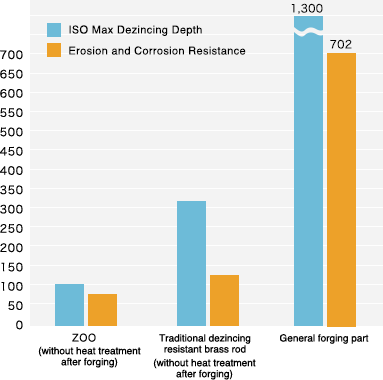

SAN-ETSU METALS’ Z00 is a new revolutionary alloy with the highest

level of dezincing resistant performance without heat treatment after the hot

forming process, developed by our latest crystal control technology.

■ZOO Chemical Composition Unit %

| Cu | Pb | Fe | Sn | Others | Zn |

|---|---|---|---|---|---|

| 62.5 | 1.5 | 0.1 | 2.0 | 0.15 | Residue |

ZOO Properties

When applying the heat treatment after hot forming, it requires not only the

equipment, technology and traceability system for the process but also the

system to control the metal structure changes which cannot be inspected

visually.

However, Z00 requires no heat treatment after hot forming yet be

able to offer the corrosion resistant performance at the equivalent level of the

traditional dezincing resistant brass rod. It also significantly reduces

manufacturing time and energy cost.

単位(μm)

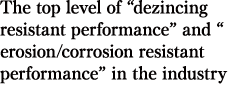

A standard dezincing resistant brass rod with the highest level of dezincing resistance and erosion/corrosion resistance performance while minimizing the deterioration of machinability. It already is applied to the various areas including water sections at home (kitchen, bathrooms and others).

■Z34 Chemical Composition Unit %

| Cu | Pb | Fe | Sn | Others | Zn |

|---|---|---|---|---|---|

| 61.5 | 2.7 | 0.1 | 0.9 | 0.10 | Residue |

Z34 Properties

Z34 was developed to be used for the locations with a direct contact with water, which is a very tough condition for brass materials. The highest level of performance was realized through the ultimate research on the optimal balance of elements and the thorough quality control.

単位(μm)

While a high dezincing resistant performance is required, the same level of machinability as C3604 is often also required at the same time. SAN-ETSU can offer DR5 as a perfect solution to such a request by achieving an optimal balance between the conflicting performance of dezincing resistant and machinability.

■DR5 Chemical Composition Unit %

| Cu | Pb | Fe | Sn | Others | Zn |

|---|---|---|---|---|---|

| 61.5 | 2.95 | ー | 0.35 | 0.10 | Residue |

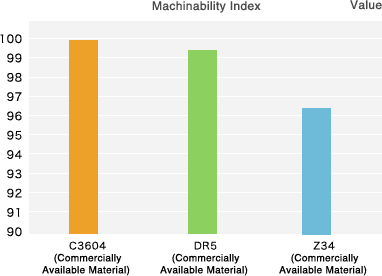

C3604 Equivalent Machinability

The machinability index was calculated based on the machining resistance (C3604 to be 100). The result of DR5 shows the equivalent value with C3604 indicating the great machinability. It is now possible to reduce the tooling ware and damages.

Click here for the dezincing resistant brass rod catalog[PDF]