Lead Free Brass

In the past, lead was added to the brass rod to improve the machinability. However lead is now known as one of the SOC and further promotion of lead-free is expected in the future. Based on such a circumstance, SAN-ETSU now use bismuth instead of lead and successfully developed the BZ series without using cadmium or lead achieving a high strength, superb machinability, corrosion resistance and non-magnetic performance equivalent to the traditional materials.

An ultimate solution for the lead free free-cutting brass rod with well-balanced machinability and workability including forging and caulking performance at a high level

Lineup of Cadmium and Lead Free Free-Cutting Brass

| Quality | Specification | ID | Characteristics / Purposes | Lead | Cadmium |

|---|---|---|---|---|---|

| Free-cutting Brass Rod BZ5 |

JIS H3250 C6801 | BZ5A | For machining and general caulking | 100ppm or less | 10ppm or less |

| BZ5U | For general caulking | 100ppm or less | 10ppm or less | ||

| BZ5F | For forging and machining without caulking | 100ppm or less | 10ppm or less | ||

| Dezincing Resistant Brass Rod BZ3 |

JIS H3250 C6801 JIS H3250 C6802 |

BZ3 | High spec material for machining | 100ppm or less | 10ppm or less |

| BZ3N | Standard material for machining | 1000ppm or less | 10ppm or less |

- ■High Machinability

- Achieved the closest machinability to the traditional material with lead in all aspects including machining resistance, shape of chips and tool life etc.

- ■Superb Forging Performance

- No requirement of special care for the fact of no use of lead from high to low temperature range and no need of setting changes throughout the forging process.

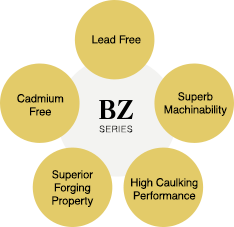

The bismuth base BZ5 series is a “lead and cadmium free

free-cutting brass rod” which will become a new global standard of the new era

with a well-balanced workability such as machinability, forging and caulking

performance at a high level.

In addition, it also offers a great thermal and electrical conductivity thus

often used for machining parts in electric, electronic and automobile

fields.

JIS code is H3250 C6801. The various type of materials for the purposes of

machining, forging, caulking and others are all including in the one code of

C6801.

- ○Lead 100ppm (0.01%) or less assured Cadmium 10ppm (0.001%) or less assured

- ○Japan Industrial Standards JIS H 3250 C6801BD-F

BZ3 series complies with the regulations of S.3874 (Safe

Drinking Water Act), AB1953 (a state Bill in California), and NSF/ANSI 61

(National Sanitation Foundation, National Standard). It is a “dezincing

resistant lead and cadmium free brass rod” with a high dezincing and corrosion

resistant performance. (the maximum corrosion depth of less than

70µm).

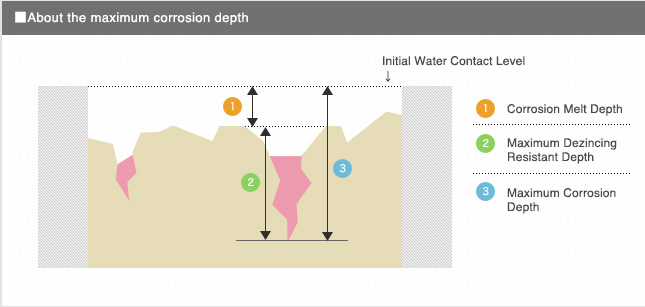

The maximum corrosion depth = the maximum depth of dezincing

depth + corrosive melt depth combined

- ○Lead 100ppm (0.01%) or less assured Cadmium 10ppm (0.001%) or less assured

- ○ Japan Industrial Standards JIS H3250 C6801BDRD-F

- ○ Lead 1000ppm (0.1%) or less assured Cadmium 10ppm (0.001%) or less assured

- ○ Japan Industrial Standards JIS H 3250 C6802BDRD-F

※“S.3874” was put in force on Jan 4, 2014.

“S.3874” is an amendment low of a federal low of SDWA (Safe

Drinking Water Act).

The amendment low regulates the lead amount for all products contacting drinking

water. It must be a content of 0.25% or less for the materials which directly

contact the drinking water.

* RD must be added after the manufacturing method (BD) for deincing resistant

according to JIS.

It was considered inevitable to add lead along with copper and zinc to the free-cutting brass rod to achieve a high machinability. However, BZ series is a breakthrough alloy realizing a superb machinability by adding bismuth (Bi) instead of lead while eliminating the use of SOC.

Bismuth (Bi) is known for its exceptional characteristic of causing little harm to human and environment in the group of heavy metal. Because of this, it is often used in some pharmaceutical products such as gastrointestinal medicine and vulnerary or cosmetic products such as lipsticks and eye shadows.

In addition, *IMS international joint research program (IMS0332) confirmed the environmental and biological influences of lead free solder materials (safety confirmation). (Research institutions: Tohoku University School of Medicine, Shizuoka University Facility of Agriculture, National Institute for Environmental Studies, Juntendo University School of Medicine, Keio University School of Medicine) As a result, the data proved that bismuth (Bi) is an environmentally and biologically friendly substance. Furthermore, the report says Bi is the best substance to replace Pb.

“PRTR Act (legislated in 1999 in Japan)” was enacted to control harmful chemical substances and recognizes 437 harmful substances. Bismuth is not, of course, one of the harmful substances recognized in the act and highly rated for its exceptional safety in the group of heavy metal.

* IMS Report Document on July 23, 2003 [EFSOT: Next Generation Environment-Friendly Soldering Technology (Evaluation of Environmental and Biological Impacts of Pb Free Solders)

- Is it okay to mix the chips from lead free materials (Bi base, Si base) with the traditional free-cutting brass materials with lead?

-

Both types of Bi and Si based chips generated through the machining processes must be separated from the traditional free-cutting brass materials with lead. The same applies to the mill ends. The reason is that both Bi and Si based materials must include only 0.1% or less Pb according to the regulation, and if the Pb volume exceeds the regulated amount it is no longer a lead free material. In addition, if Bi and/or Si based materials are mixed with the traditional lead materials, the mechanical property, machinability and orthotropic property will be deteriorated in comparison to the traditional material. Thus it is necessary to control them separately.

- Bi is a kind of metal and the atomic No. of Bi is right next to lead, but is Bi still not one of the harmful substances?

-

EFSOT (Next Generation Environment-Friendly Soldering Technology) which is one of the IMS international project evaluated the biological influences of lead free solders, and they reported the result of their study on the toxicity of Bi. The report shows that the Bi has significantly less toxicity in comparison to Pb or Sb.

- Bi reserve is very little and it is easily expected that we will face the issue of unavailability of Bi in market as Bi will be widely used as a replacement of Pb in a wide range of fields. Furthermore, in general, Bi is a by-product of Pb and 30 to 200 tons of lead is produced in order to obtain one tone of Bi. Meanwhile, they say that lead offers very limited commercial value thus most of it will be disposed. Is this a fact?

-

The reason for China occupies a high share of Bi production volume is that Bi is an accessory mineral of tungsten and tin deposit. It is not a by-product of lead. The total metal volume from the Shizhuyuan deposit, the largest deposit in China, includes 750,000 tons of WO3, 450,000 tons of Sn and 300,000 tons of Bi. With this figure, Bi is more than just a by-product. In addition, 160,000 tons of WO3 and 79,000 tons of Bi mined at one of the recently found deposit, Nui Phao, located at Northern Vietnam. Furthermore, it was confirmed that approximately 120,000 tons of Bi exists at the mining property located in Northeastern Mongol where is currently under prospect by a junior company of Canada. Yet, it is true that availability of Bi is limited, however it also indicates a high possibility of forming an independent mineral phase, differently from indium and cadmium. This means that more of the large Bi deposits could be discovered in the future.

Should you have further questions or request for more information, please contact us via Contact Form.

![Safe Metal [Bismuth (Bi)] Atomic No. 83](images/leadfree_h3_1.png)